Unveiling Technology Solutions by BatX Energies

In the fast-paced world of today, it is needless to say that there is indeed a greater need than ever for efficient and sustainable energy solutions. Delivering just that, BatX Energies, the leading lithium-ion battery recycling company in India, equipped with advanced procedures is at the forefront of developing technological solutions for efficient and sustainable energy solutions. Want to dig deeper?

Let us get into the blog to explore the technology solutions by BatX Energies. Let’s go!

Table of ContentsTechnology Solutions by BatX Energies Reverse Logistics HUB & SPOKE Model Using Tools like Blockchain, AI, and ML Segregation: Testing and Sorting Using a Unique Mechanical Process Chemical (Hydrometallurgical) Process |

Technology Solutions by BatX Energies

Let us explore the technology solutions by BatX Energies one by one:

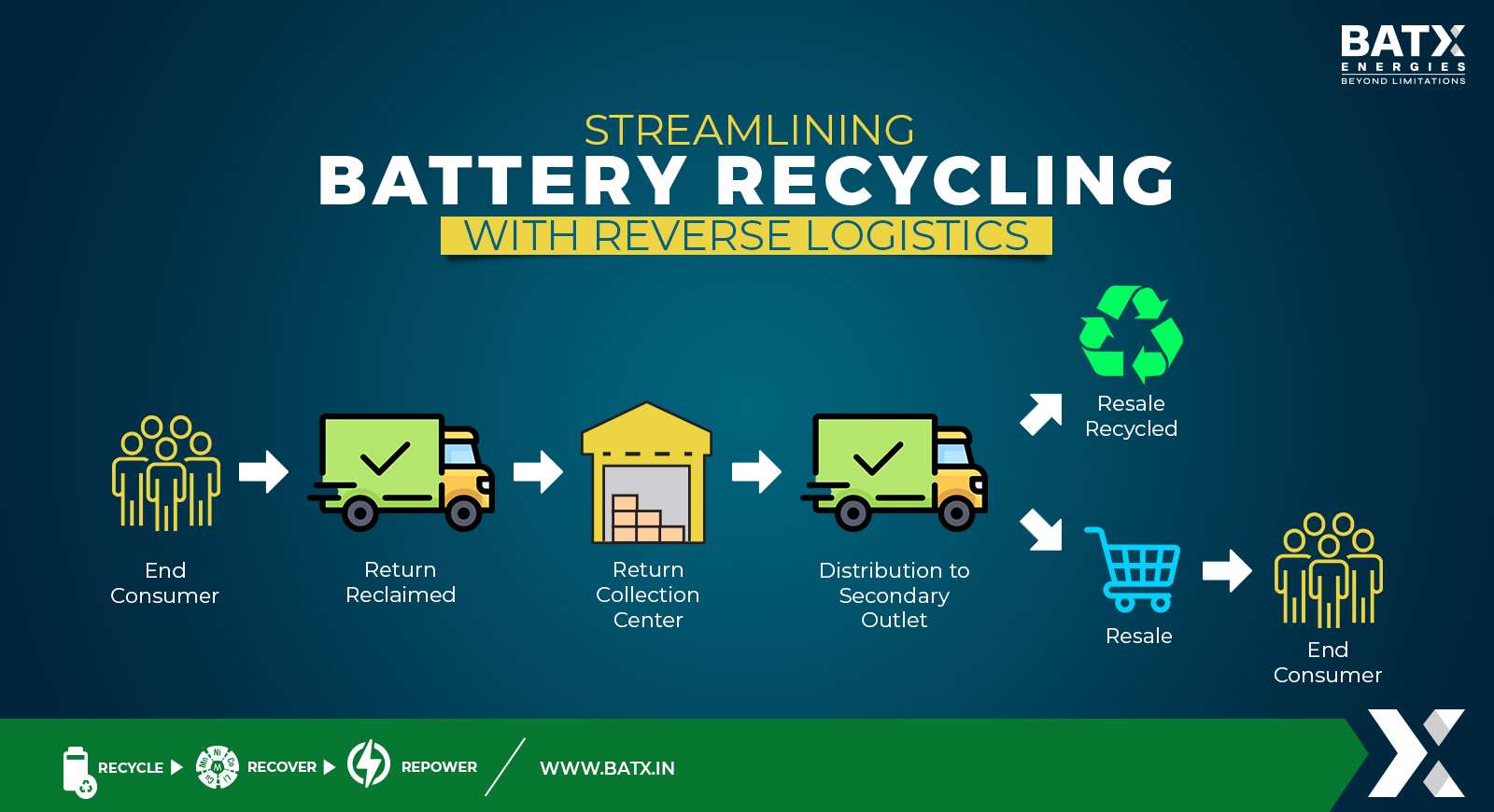

Reverse Logistics HUB & SPOKE Model

The Reverse Logistics HUB & SPOKE Model is a fundamental component of technological solutions by BatX Energies. With the help of this model, BatX Energies has the flexibility to source end-of-life Lithium-ion cells from virtually any geographical location (SPOKE) and transport them safely and efficiently for recycling to our manufacturing facility (HUB).

Using Tools like Blockchain, AI, and ML

BatX Energies is aware of how critical it is to use technology to improve process effectiveness and general safety. BatX Energies uses the latest technologies such as Artificial Intelligence, Machine Learning, and Blockchain. Using these advanced tools, BatX Energies can maximize the quality, consistency, and safety requirements of its raw materials, guaranteeing the best possible results in its battery recycling and refurbishment operations.

Segregation: Testing and Sorting

Every shipment of used lithium-ion cells is put through a barrage of tests at the BatX Energies to evaluate the overall quality of cells, the amount of charge left in them as well as their cell chemistry and composition. BatX Energies can identify and classify cells according to the type of battery they are made of through this segregation testing and sorting process, which maximizes the productivity and efficiency of their recycling process.

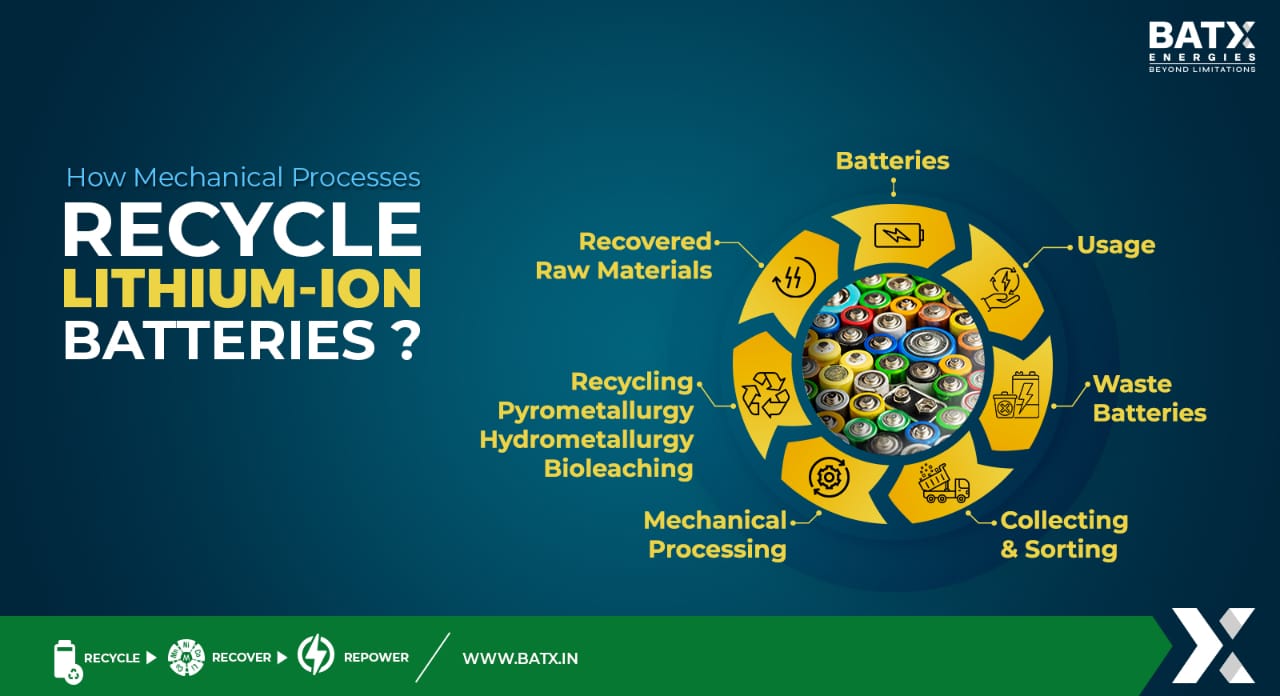

Using a Proprietary Mechanical Process

The proprietary seven-layer mechanical process created by BatX Energies makes it simple to extract valuable components from lithium-ion batteries. The process includes shredding and crushing for easy separation of Black Mass from the other secondary materials and maximizing the yield of both. The company’s objective of creating a sustainable circular economy is aided by the mechanical process, which guarantees maximum production and purity.

Chemical (Hydrometallurgical) Process

BatX Energies uses proprietary hydrometallurgical processes that have been specifically synthesized to be used repeatedly and infinitely. This technique recovers high-grade salts of rare earth metals like manganese, nickel, cobalt, and lithium. After being mined, these metals are prepared for reintroduction into the supply chain for the production of lithium-ion batteries, which will minimize waste and lessen the need for mining.

In Closing

With the advanced technology solutions by BatX Energies, including reverse logistics model, technology tools, testing and sorting, mechanical process, and hydrometallurgical process, the door for a more promising and ecologically conscious future is here.

Want to know more about the technology solutions by BatX Energies?

Come visit our website!