As the demand for electric vehicles (EVs) and renewable energy storage continues to climb, transport batteries, particularly lithium-ion batteries, have become a crucial component of the global market. These batteries’ economics significantly impact the industry and encourage sustainable practices. Let us get into the blog to discuss the economics of transport batteries in the global market, including production costs, recycling, and market trends!

Table of ContentsThe Economics of Transport Batteries in the Global Market Raw Materials Manufacturing Process Economies of Scale and Scope Recycling Batteries and The Circular Economy Effect on the Environment Recovering Priceless Materials Policies and Rules Market Trends and the Projection Price Volatility Potential for Growth and Global Demand Trade and International Competition |

What are Transport Batteries?

In simple terms, transport batteries are rechargeable energy storage units. These batteries are specifically designed for use in electric vehicles (EVs), hybrid electric vehicles (HEVs), and other types of transportation. These batteries give the vehicle the electricity it needs to go forward and power all of its electrical systems. The lithium-ion battery is the most popular form of transport battery since it outperforms conventional lead-acid batteries in terms of energy density, longevity, and charging speed. To electrify transportation, lower greenhouse gas emissions, and advance sustainable mobility solutions, transport batteries in the global market have a vital role to play.

The Economics of Transport Batteries in the Global Market

The Cost Factors

Raw Materials

Vital raw materials like lithium, nickel, cobalt, and manganese are essential for the production of batteries. The availability and cost of these raw materials are influenced by supply-demand dynamics, which can impact battery prices.

Manufacturing Process

Setting up battery manufacturing facilities necessitates a sizable capital investment in infrastructure and equipment. Furthermore, production costs can be impacted by labor expenses and the degree of automation in the manufacturing process.

Economies of Scale and Scope

Increased production volumes frequently result in economies of scale, which lower costs. EV manufacturing integration can improve production procedures and cut costs.

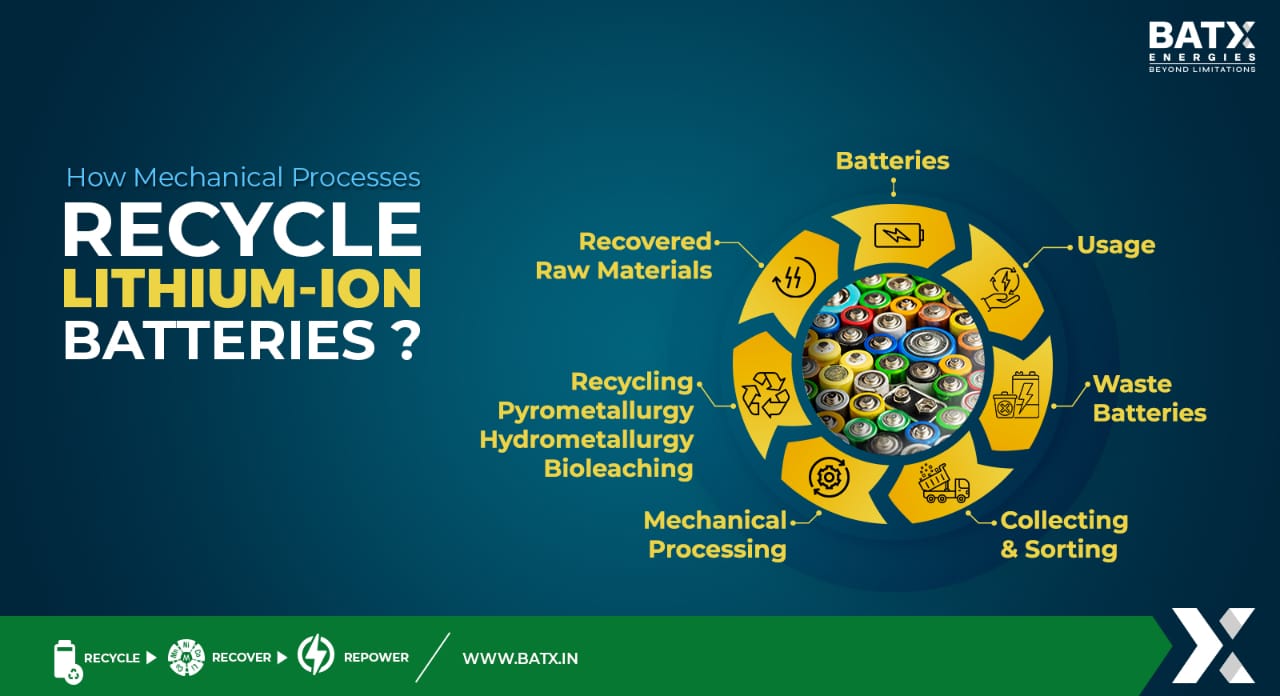

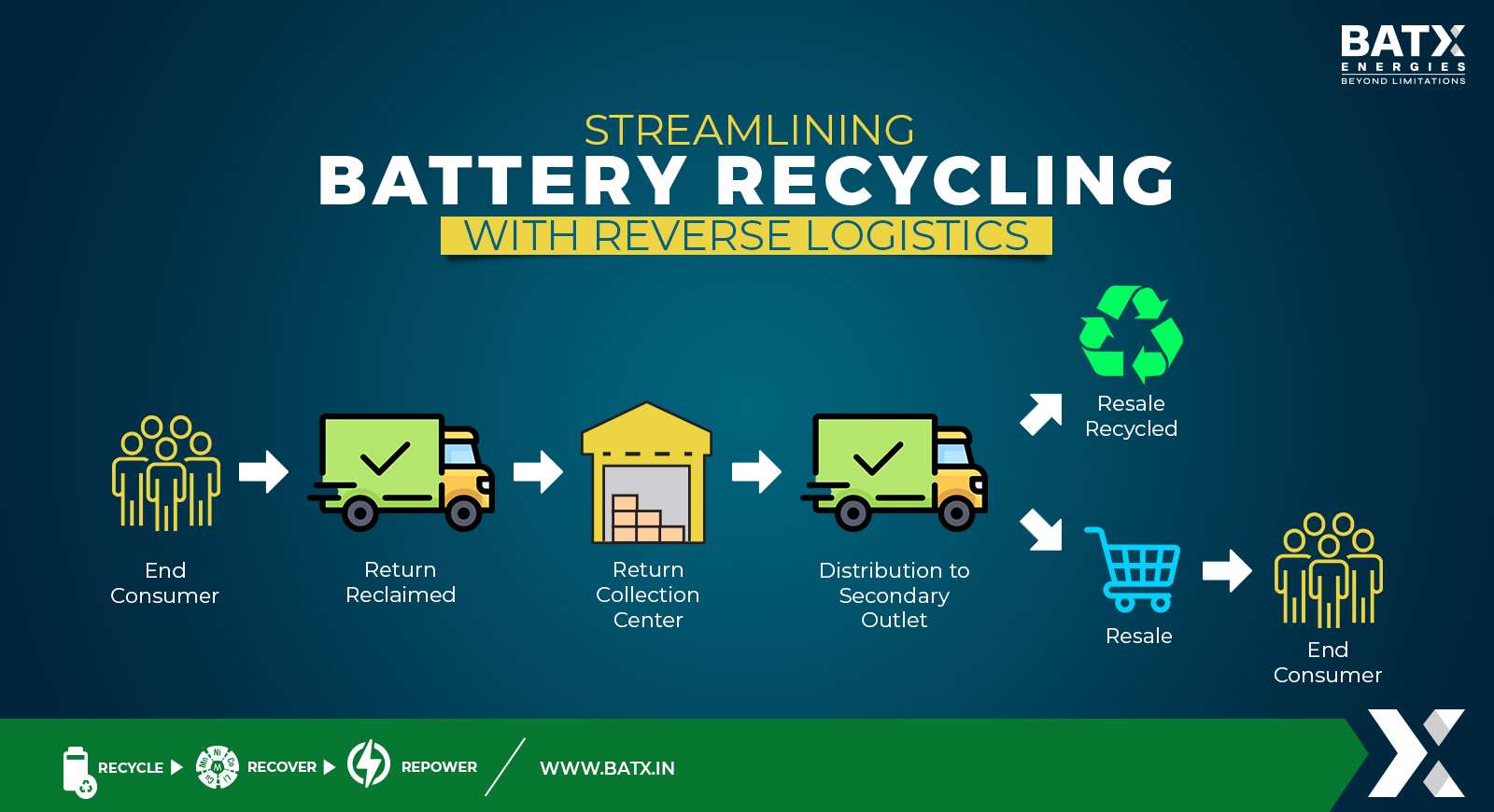

Recycling Batteries and The Circular Economy

Effect on the Environment

Recycling batteries contribute to a reduction in the carbon footprint associated with the production and extraction of raw materials. Recycling makes it possible to recover and reuse valuable resources, which lessens the demand for fresh raw material extraction.

Recovering Priceless Materials

Recycling procedures recover these priceless components like Lithium, Nickel, Cobalt, and Manganese from old batteries, decreasing dependency on raw resources. Recycling can result in secondary goods including plastic, aluminum, copper, and stainless steel, offering new revenue streams.

Policies and Rules

Battery makers are held liable under Extended Producer Responsibility (EPR) laws for the collecting and recycling of used batteries. Governments and other organizations offer incentives to encourage the construction of recycling infrastructure.

Market Trends and the Projection

Price Volatility

Raw material costs influence battery prices and market dynamics. Examples of these materials are lithium and cobalt. Also, as a result of technological advancements in the production of batteries, costs can be reduced giving way to greater affordability.

Potential for Growth and Global Demand

As the demand for EVs rises, so does the need for transport batteries, opening up new market opportunities. Batteries are essential for storing renewable energy, and the rising use of renewable energy sources creates a significant market opportunity.

Trade and International Competition

China has become a leader in battery manufacturing, impacting the overall dynamics of the worldwide market. Even with huge competition, for battery producers and recyclers, emerging markets present potential development prospects.

The Bottom Line

The cost of raw materials, manufacturing procedures, battery recycling, and market trends are just a few examples of the many variables that go into the economics of transport batteries in the global market. To properly traverse the industry, stakeholders must comprehend these dynamics. Transport batteries in the global market can prosper and help create a more sustainable and greener future by putting a strong emphasis on cost reduction, eco-friendly recycling methods, and capitalizing on market trends.