Reverse Logistics is a supply chain sector that plans and controls moving goods from consumption or customers back to the seller or distributor to recycle, repair, or recover. Without proper monitoring and managing the reverse logistics, a company can lose millions of dollars in potential value. It has a greater importance from now till future. When executed properly, reverse logistics reduces the waste we generate, generates new revenue streams, and improves customer satisfaction. In this blog, we will acknowledge Streamlining Battery Recycling with Reverse Logistics.

Table Of Contents:

Reverse Logistics Vs. Traditional Logistics

Control Pollution

Reduce Cost Of New Batteries

Keeps Dangerous Materials Out Of Landfills

Challenges in Battery recycling

Lack Of Awareness

Limited Recycling Infrastructure

Economic Viability

Streamlining Battery Recycling with Reverse Logistics

Process the return

Returns Management

Repair

Recycle

Waste Management

Reverse Logistics Vs. Traditional Logistics

In traditional logistics, the product flow begins with suppliers and moves to a factory. Afterward, the products go to the customer.

Reverse logistics is implemented in the opposite direction from traditional logistics. Here the goods are moved from consumption or customers back to the seller or distributor.

Benefits of Battery Recycling

Batteries are easy to dispose of and recycle. Battery recycling simply means reducing the number of batteries getting disposed of as solid waste. Let’s dive into the benefits of battery recycling.

Control Pollution

Batteries are made up of harmful chemicals which can be harmful to human health. The plastic components, heavy metals, and acids are used in batteries, if they leak into soil the toxins can pollute water resources and destroy wildlife. Hence, battery recycling keeps the toxins from the environment so that water, soil, and air are not polluted.

Reduce Cost Of New Batteries

During battery recycling, the recycled materials can be further used for manufacturing. It reduces the production costs and hence reduces the cost of new batteries.

Generates New Jobs

Battery recycling plays an important part in creating new jobs in the manufacturing and recycling industries. A huge manpower is needed to recycle batteries so, recycling generates new jobs and revenue.

Keeps Dangerous Materials Out Of Landfills

Batteries contain the materials like cadmium, lead-acid, and lithium-ion. When disposed of in a landfill, batteries break down and toxic materials can reach waterways and oceans. Hence battery recycling protects your health and environment.

Challenges in Battery recycling

Lack Of Awareness

People still use traditional disposal methods such as landfilling and incineration. They are not aware of the benefits of battery recycling with reverse logistics.

Limited Recycling Infrastructure

Currently, there is limited recycling infrastructure as compared to growing demand. The lack of recycling infrastructure is one of the biggest issues with battery recycling. This leads to disposal in landfills where decomposing takes hundreds of years.

Economic Viability

The cost of battery recycling can vary over time. It depends on factors such as market demand for recycled materials and the cost of recycling technologies.

Streamlining Battery Recycling with Reverse Logistics

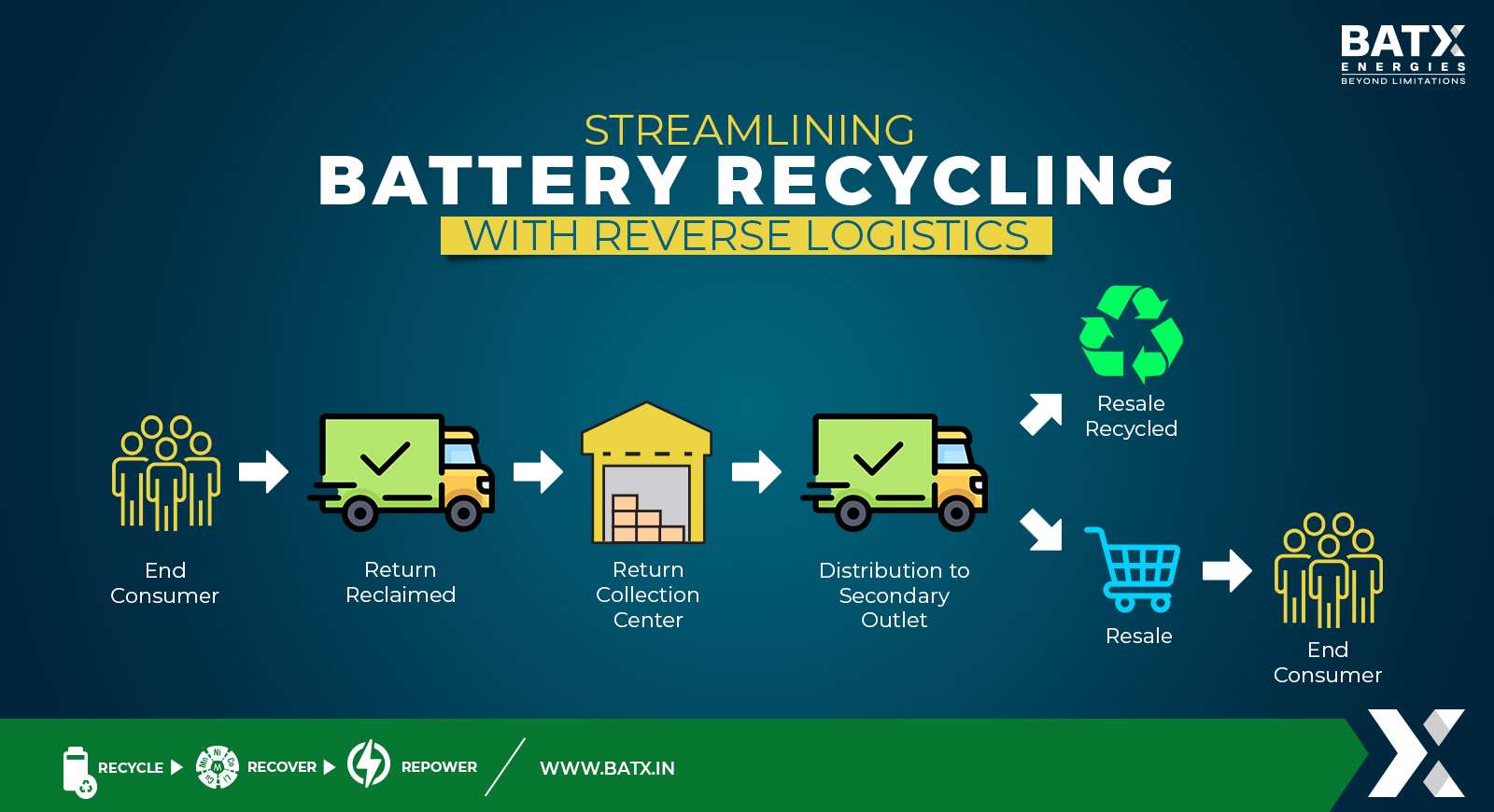

Battery recycling is key to a clean future. Let’s look into the process of battery recycling with reverse logistics.

Process the return

The return process begins when a customer wants to return the product and ends when a business collects, sorts, refunds, and restocks the items. It involves scheduling return shipments, approving the refunds, and replacing the damaged goods.

Returns Management

When the returned product arrives, inspect it and determine the return category. Sort the products into fix, recycle, or refurbish disposition options. These activities must be fast, controllable, and straightforward.

Keep Returns Moving

Here the daily waste is reduced by processing returned products, handling refunds or exchanges, and finally returning the repairable items to the repair department.

Repair

After reviewing the returned item and determining whether it can be repaired. If repair is possible pass it to the technicians or repair specialist. If repair is not sold any sellable parts.

Recycle

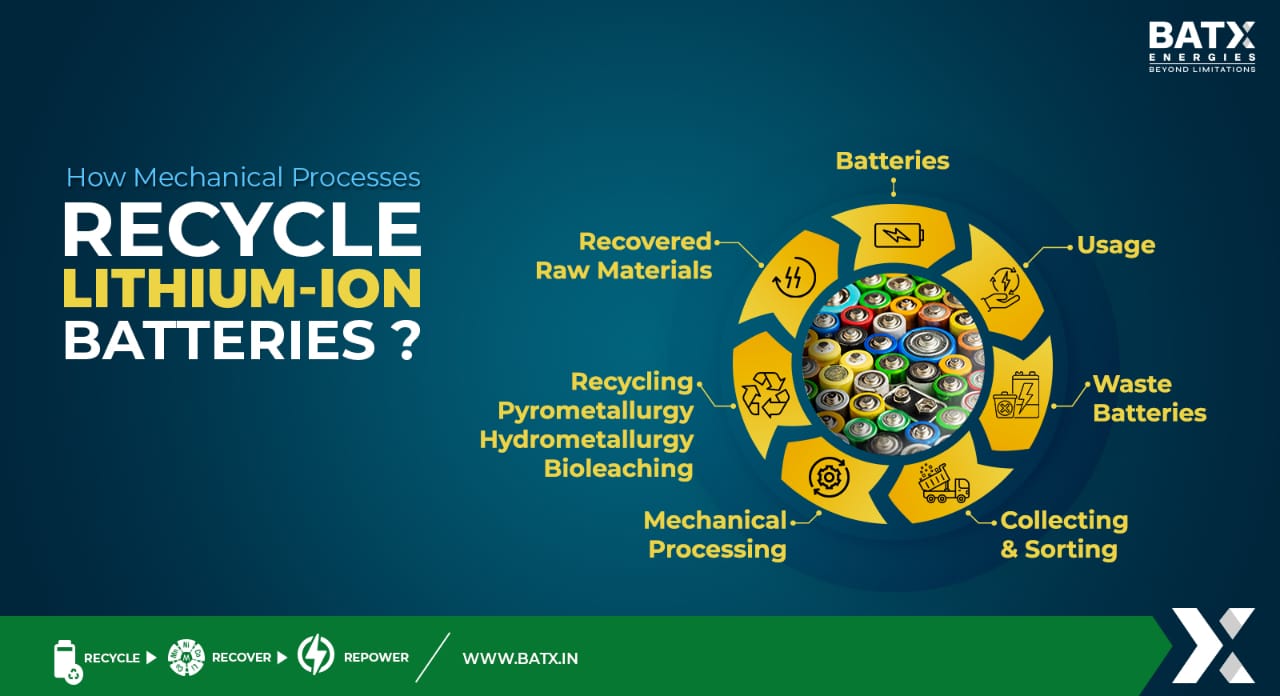

If the products or any parts cannot be repaired, reused, or resold then sent to the area of recycling. The Battery ecycling with Reverse Logistics phase includes:

Mechanical Separation: It is a technique of separating mechanical components like plastics, lead, and sulfuric acid and recycling them individually.

Hydrometallurgical Process: It is a technique of using water-based solutions to extract metals from their ores or batteries. Metals like lithium, cobalt, nickel, and copper are recovered from the solution for reuse.

Pyrometallurgical Process: This method involves heating the battery parts really hot to split the metals from everything else.

Waste Management

Improper waste management can degrade your health as well as the environment. Almost everything is recyclable, if anything can be recycled then it is disposed of safely to reduce environmental risk.

Conclusion

Reverse logistics plays a pivotal role in streamlining battery recycling processes and advancing sustainability goals. By embracing a circular economy approach, stakeholders can transform the way batteries are managed throughout their lifecycle, from production to disposal. Through effective collection, transportation, and recycling practices, reverse logistics enables the efficient recovery of valuable resources while minimizing environmental impact. As we navigate towards a greener future, Battery Recycling with Reverse Logistics will be instrumental in creating a more sustainable and resilient society.