Lithium-ion batteries contain toxic metals like cobalt, nickel, and manganese, which leakage into waterfalls and ecosystems can cause harmful effects. Human exposure to lithium-ion batteries can cause hazardous symptoms like nausea, vomiting, loss of appetite, and weakness. Hence lithium-ion batteries must be recycled to provide a better environment for both humans and animals. Let’s explore the process of mechanical recycling for lithium-ion batteries to reduce its impact on the ecosystem.

Table Of Contents:

Process Of Mechanical Recycling for Lithium-Ion Batteries

Collection and Sorting

Dismantling

Size Reduction

Separation Of Component

Purification

Waste Management

Challenges in Mechanical Recycling for Lithium-Ion Batteries

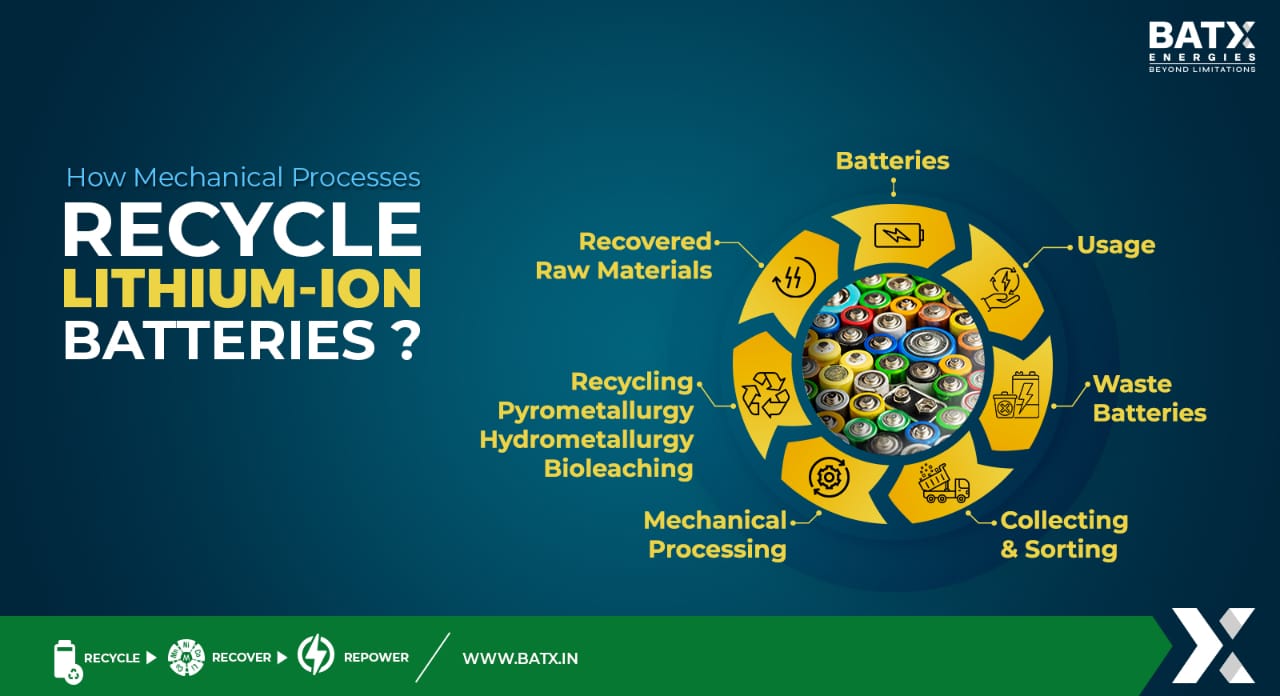

Process Of Mechanical Recycling for Lithium-Ion Batteries

Recycling lithium-ion batteries helps to return valuable resources like lithium and cobalt so that we don’t have to dig into the ground to find new materials, which is good for the earth.

Collection and Sorting

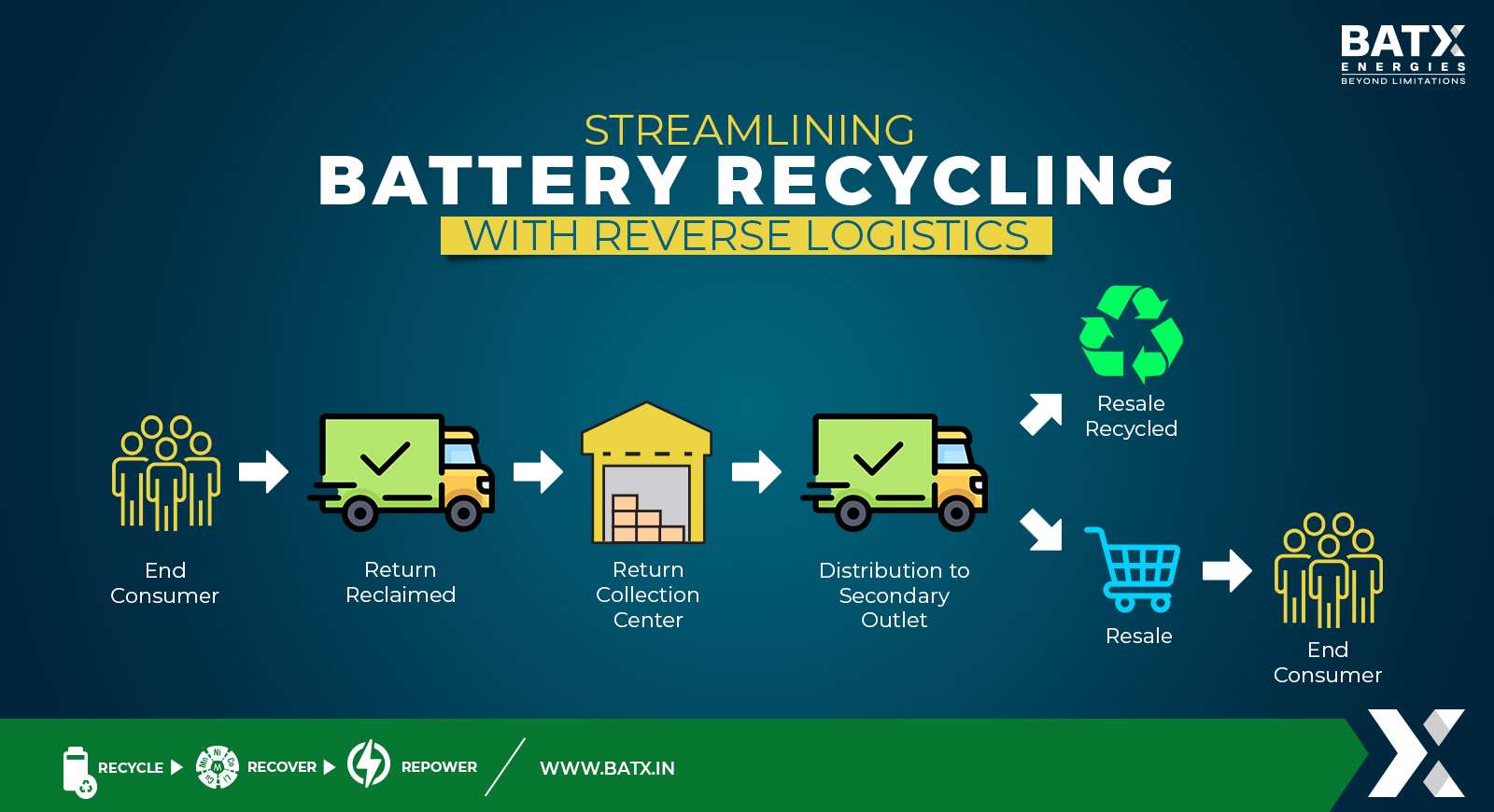

The first step for mechanical recycling for lithium-ion batteries is collection and sorting. Here the collection of Lithium-ion batteries is done from consumer electronics like smartphones, laptops, tablets, electric vehicles, and energy storage systems. After collection, they are transported to the specialized recycling center avoiding the risk of damage or leakage. The batteries are stored based on voltage, capacity, and internal resistance.

Dismantling

Dismantling plays an important role in the separation and recovery of valuable materials. After collection and sorting, the lithium-ion battery is dismantled manually in the laboratory to obtain the spent anode, cathode, separator, and electrolyte.

The cathode determines the capacity and voltage of the Lithium-ion battery, whereas the anode sends electrons through a wire. Electrolytes allow movements of ions only and the separator is considered the absolute barrier between cathode and anode. In the case of a large number of lithium-ion batteries, they should be dismantled on an industrial scale.

Size Reduction

After batteries are dismantled, the used batteries are broken down into smaller components for further processing in recycling. Size reduction helps to extract valuable materials like cobalt, nickel, and other metals. It helps to crush them into smaller pieces and optimize the efficiency of the extraction process.

Separation Of Component

Mechanical processes are used to separate the different components of lithium-ion batteries. It allows to separate the valuable materials like electrode materials (such as lithium, cobalt, nickel, and manganese) and recovered them separately. Using an eddy current, aluminum is separated. The material goes to the air separator where it is separated according to the density, size, and shape difference.

Purification

After the extraction of valuable materials and metals, the purification process removes impurities and contaminants. It is done by filtration, chemical treatment, and electrolysis process to separate desired valuable materials from impurities.

After purification, the recovered materials can used to manufacture new batteries. It can be incorporated into the production of electronic devices or can be used in manufacturing EV batteries. Generally, using the recovered battery materials ensures cost and energy savings.

Waste Management

Not all materials can be recycled from lithium-ion batteries, which have negative impacts on humans, plants, animals, and the environment as a whole. After reducing and reusing the valuable materials from lithium-ion batteries, the toxins are managed properly to save the environment from harmful materials.

Challenges in Mechanical Recycling for Lithium-Ion Batteries

Achieving positive outcomes goes hand in hand with facing challenges during mechanical recycling for lithium-ion batteries. Here are some of the difficulties linked to mechanical recycling for lithium-ion batteries.

- Lithium batteries are difficult to recycle and contain low-recovery materials. They come in different chemistries and each one requires a different recycling process.

- Lithium-ion batteries are highly reactive so it is difficult to handle them. Mishandling can harm the environment.

- Mechanical recycling for lithium-ion batteries requires high temperature, strong acid leaching, and extensive gas treatment.

- The recycling process of lithium-ion batteries is at risk of generating large amounts of harmful emissions which lead to environmental impact.

- The recycling rate of lithium-ion batteries is only 5% which makes the recycling process expensive.

Conclusion

Lithium-ion batteries contain harmful chemicals which increase the risk of hazardous waste. It must be recycled to make Earth a better place to live. The mechanical recycling for lithium-ion batteries is intended to ensure that they are recycled correctly to avoid entry into the environment of dangerous substances.

Mechanical recycling for lithium-ion batteries requires high investments in technology for collection, transportation, and management. Addressing these challenges Batx Engeries has been doing its best to eliminate toxic materials from lithium-ion batteries making the environment safer for humans, plants, and animals. They are trying to recover valuable materials and metals from lithium-ion batteries, save on the costs and emissions associated with mining, and make Earth a better place to live.