Reverse Logistics

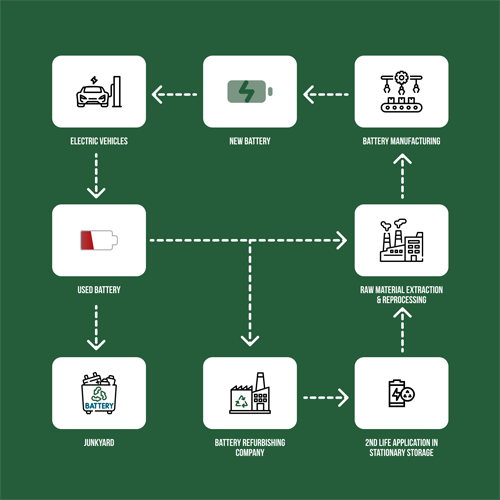

HUB & SPOKE Model – We have the flexibility to source end-of-life Lithium-ion cells from virtually any geographical location (SPOKE) and transport them safely and efficiently for recycling to our manufacturing facility (HUB).

Battery Sources – Our supply of used Li-ion cells comes from various sources, but is always procured in the safest, most ethical and responsible way. Most of our cells tend to come from Electronics, EVs as well as other devices. For the time being, we source these cells from all over India. But we are open to sourcing from abroad as well.

Battery Type – We procure the three most common types of used Lithium-ion cells which are Prismatic Cells, Cylindrical Cells and Pouch Cells.

Leveraging Technology – We utilise all the latest technologies such as Artificial Intelligence, Machine Learning and Blockchain to constantly improve our efficiency levels as well as overall safety, raw material quality and consistency.

Segregation

Testing and Sorting – When a shipment of used Lithium-ion cells arrives at our facility, it is immediately put through a barrage of tests, which is the first step in our proprietary automated process. This testing procedure consists of checking the overall quality of cells, the amount of charge left in them as well as their cell chemistry and composition.

Making Batches – Although our process is cell chemistry agnostic, we divide and sort and divided based on battery type. This helps us in getting the maximum output at the end of the process.

Discharging Cells – As per our Net Zero Waste, Zero Emissions initiative, we made a conscious decision to completely discharge all the remaining energy from batteries which is used to power our plant.

Mechanical Process

Proprietary Mechanical Process – Our proprietary seven-layer mechanical process, which includes shredding and crushing was created specifically to allow for easy separation of Black Mass from the other secondary materials and maximise the yield of both.

Black Mass – The primary product of our mechanical process is high-grade Black Mass with less than 1% impurities. We have reached a stage in our efficiency and consistency wherein we are able to produce this level of purity in every batch.

Secondary Products – Our process ensures that all the Secondary Products from Black Mass extraction such as Plastic, Aluminium, Steel and Copper are all neatly separated, collected and ready to sent for their next application.

Chemical (Hydrometallurgical) Process

Reusable Chemicals – All the chemicals that we use in our proprietary Hydrometallurgical processes have been specifically synthesized to be used repeatedly and infinitely. After they perform the extraction of the Rare Earth metals, they return to their original state.

Rare Earth metals – The end result of our Hydrometallurgical Process are high-grade salts of Lithium, Cobalt, Nickel & Manganese, which are ready to be re-introduced into the Lithium-ion cell manufacturing supply chain.

Net Zero Waste and Zero Emissions – One of the key reasons for BatX Energies’ existence is to reduce the pollution that is created from mining across the world and also to reduce waste that is generated from batteries that are in landfills across the world. To that end, we have taken all possible measures to ensure that our process produces Net Zero Waste and Zero Emissions.

- Office No. 7, 6th Floor, Enkay Tower, Udyog Vihar Phase V Gurugram - 122022