The global shift towards electric vehicles (EVs) is gaining momentum, and India is emerging as a significant player in the manufacturing of EV batteries. With a strong focus on clean and sustainable transportation, the Indian government, along with domestic and international companies, is driving the growth of EV battery manufacturing in the country. In this blog post, we will explore the reasons behind the rise of EV battery manufacturing in India, the key players, government initiatives, and the potential impact on the automotive sector.

|

Table of contents Key Drivers of EV Battery Manufacturing in India Government Initiatives and Policies: Growing Demand for Electric Vehicles: Strategic Partnerships and Investments: Localization of the Supply Chain: Technological Advancements and Research: Economic and Environmental Impact: Future Outlook and Challenges: |

Key Drivers of EV Battery Manufacturing in India

Government Initiatives and Policies:

India’s government has taken proactive steps to promote the adoption of EVs and boost domestic manufacturing. Initiatives such as the Faster Adoption and Manufacturing of Electric Vehicles (FAME) scheme, the National Electric Mobility Mission Plan (NEMMP), and the Phased Manufacturing Program (PMP) provide incentives, subsidies, and tax benefits to manufacturers. These policies have attracted investments and facilitated the growth of EV battery manufacturing in India.

Growing Demand for Electric Vehicles:

India’s rapidly growing population, urbanization, and concerns about air pollution have fueled the demand for electric vehicles. As consumers become more environmentally conscious, there is a shift towards cleaner and greener mobility solutions. The increasing demand for EVs has created a favorable market for EV battery manufacturers, prompting domestic and international companies to invest in manufacturing facilities in India.

Strategic Partnerships and Investments:

To bolster the EV battery manufacturing ecosystem, both domestic and international companies have formed strategic partnerships and made significant investments in India. Global players like Tesla, LG Chem, and Panasonic have announced plans to set up manufacturing facilities or collaborate with Indian companies. Additionally, Indian conglomerates like Tata Group, Mahindra & Mahindra, and Reliance Industries have made substantial investments in EV battery manufacturing.

Localization of the Supply Chain:

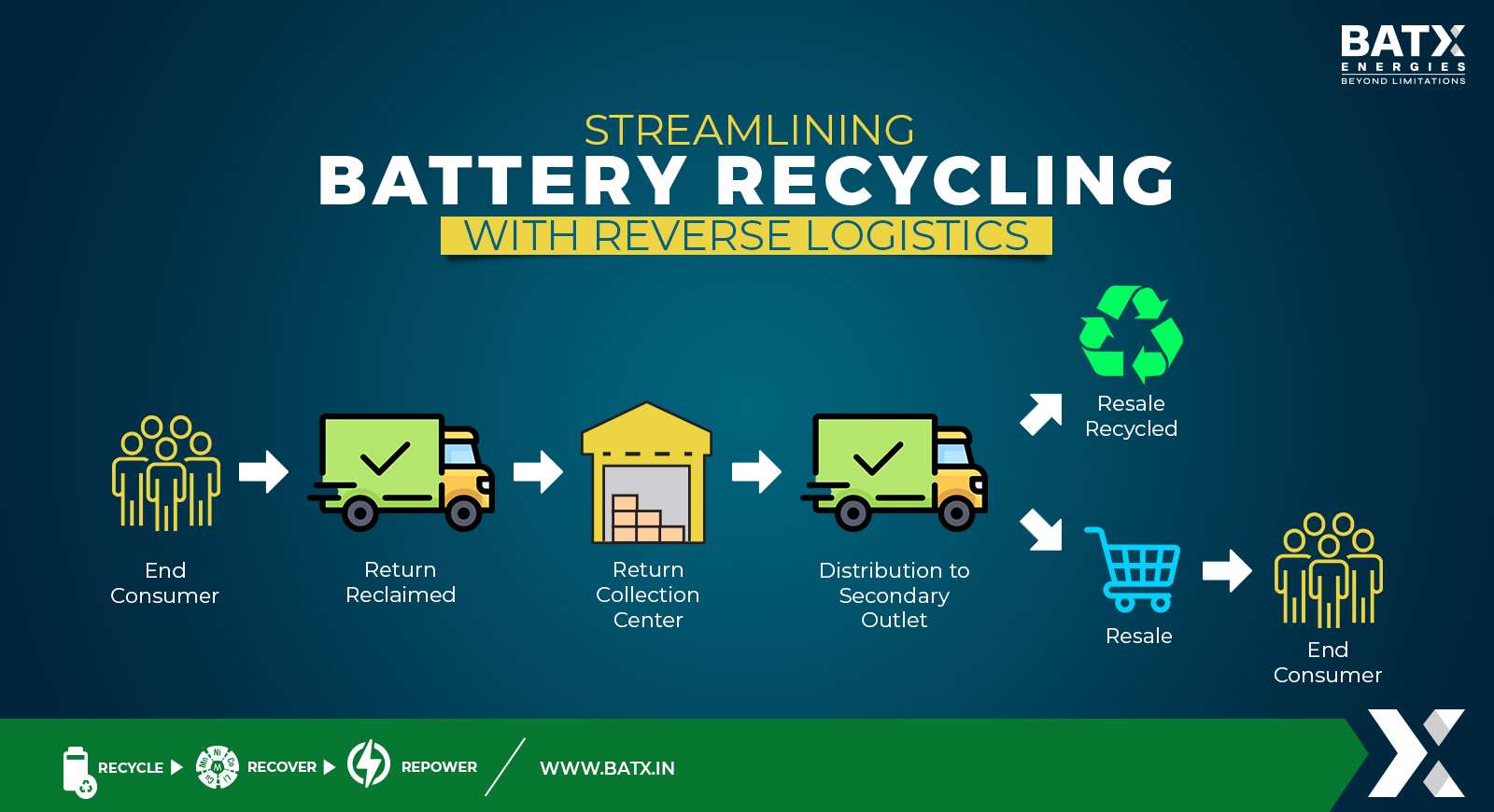

To reduce costs and ensure a sustainable EV battery manufacturing ecosystem, localization of the supply chain is vital. India’s efforts to localize the production of battery components and raw materials like lithium, cobalt, and nickel are gaining momentum. By developing a self-reliant supply chain, India aims to reduce its dependence on imports, enhance cost competitiveness, and establish a robust EV battery manufacturing ecosystem.

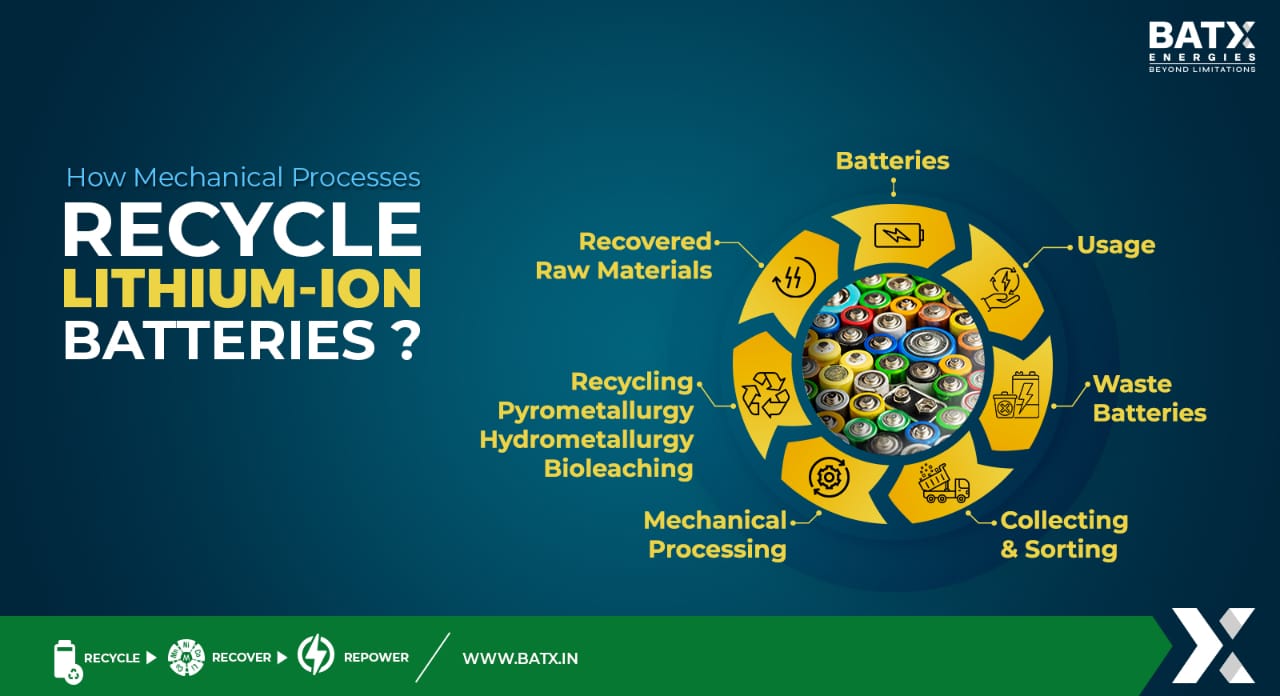

Technological Advancements and Research:

The rise of EV battery manufacturing in India has spurred technological advancements and research in the field. Companies are investing in research and development to improve battery performance, increase energy density, enhance charging infrastructure, and reduce costs. Collaborations between industry, academia, and research institutions are driving innovation, supporting the development of cutting-edge battery technologies, and addressing challenges such as range anxiety and charging time.

Economic and Environmental Impact:

The growth of EV battery manufacturing in India has significant economic and environmental implications. The establishment of manufacturing facilities has the potential to create employment opportunities, boost local economies, and contribute to India’s vision of becoming a manufacturing hub for EVs and batteries. Moreover, the widespread adoption of EVs powered by domestically manufactured batteries will help reduce greenhouse gas emissions, improve air quality, and promote sustainable transportation.

Future Outlook and Challenges:

While the rise of EV battery manufacturing in India is promising, certain challenges need to be addressed. These include the development of a robust charging infrastructure, the availability of skilled labor, the need for continuous research and innovation, and cost competitiveness in the global market. Overcoming these challenges will be crucial for India to establish itself as a leading player in the EV battery manufacturing sector.

Conclusion:

The rise of EV battery manufacturing in India represents a significant step towards achieving sustainable and clean mobility. With favorable government policies, growing demand, strategic partnerships, and technological advancements, India is poised to become a key global player in EV battery production. The localization of the supply chain, investments in research, and the environmental benefits of electric mobility further enhance India’s position in the global EV market. As the EV industry continues to evolve, India’s focus on battery manufacturing sets the stage for a greener future and reinforces the country’s commitment to sustainable transportation.