Metals play a crucial role in various industries, from electronics to construction, and their purity is of utmost importance for optimal performance. Hydrometallurgical processes have emerged as a reliable and efficient method for obtaining pure metals. This blog will delve into the hydrometallurgical process for obtaining pure metals and its significance in extracting these essential resources.

Table of contentsThe Hydrometallurgical Process for Pure Metal Extraction Leaching Solution Purification Metal Recovery Refining Benefits of Hydrometallurgical Processes for Pure Metal Extraction |

Understanding Hydrometallurgy

Hydrometallurgy is a branch of metallurgy that focuses on using aqueous solutions to extract and purify metals from ores, concentrates, or recyclable materials. This innovative approach minimizes the need for energy-intensive physical methods and offers significant advantages in terms of purity and sustainability.

The Hydrometallurgical Process for Pure Metal Extraction:

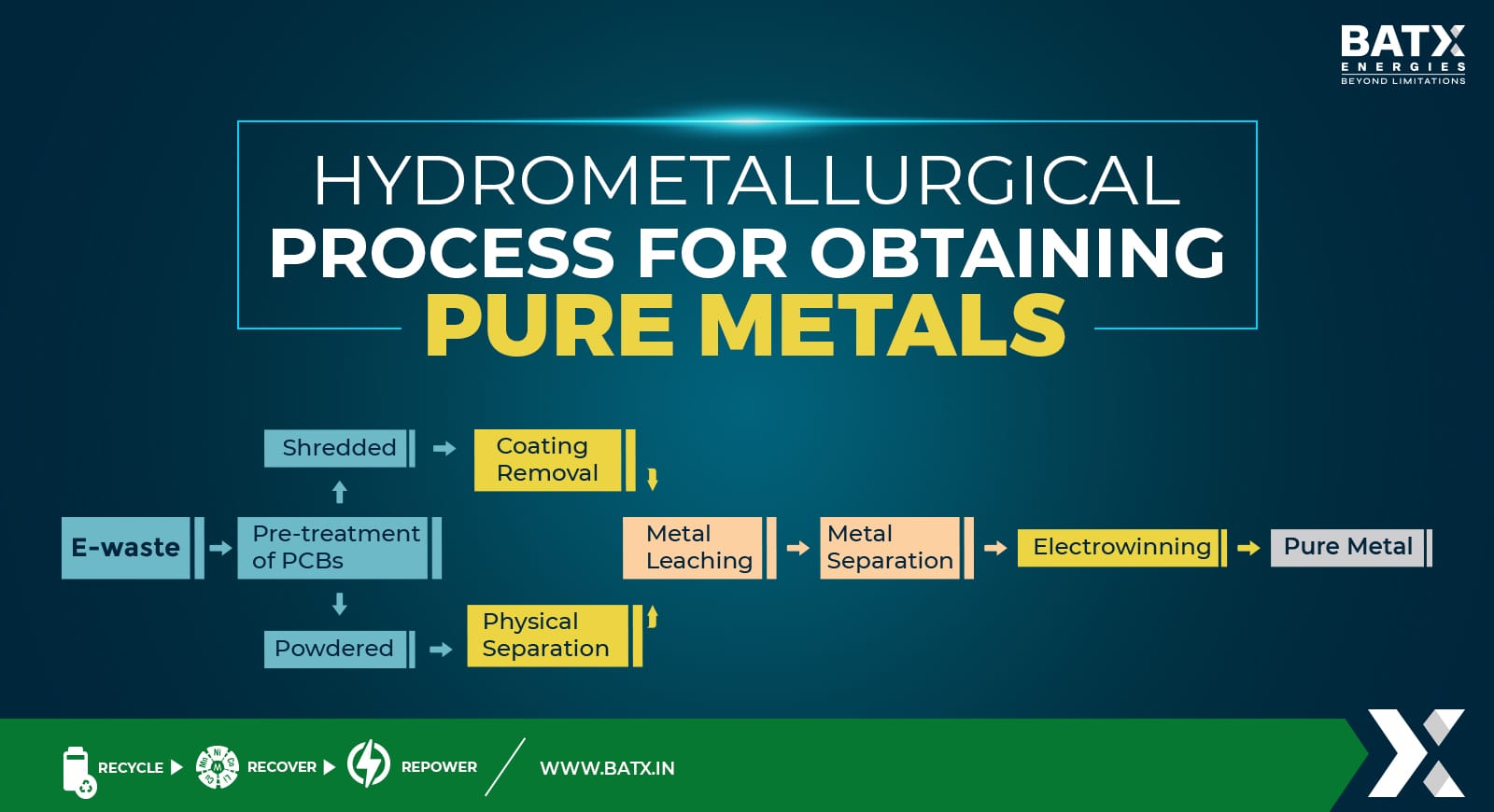

There are several key steps to be involved in the hydrometallurgical process for obtaining pure metals effectively. Let’s explore these steps in detail:

Leaching:

The process begins with leaching, where the metal-bearing material is exposed to a suitable solvent. This solvent, often an acid or a base, selectively dissolves the metal of interest while leaving impurities behind. Leaching can be conducted in tanks, heaps, or columns depending on the specific requirements.

Solution Purification:

Once the metal is leached into the solution, it undergoes purification to remove impurities such as undesired metals, non-metallic elements, and organic compounds. Several purification techniques are employed, including solvent extraction, precipitation, ion exchange, and filtration. These methods selectively remove impurities, ensuring a higher level of purity in the final metal solution.

Metal Recovery:

After purification, the next step is metal recovery, where the metal ions are converted into their pure metallic form. Various techniques can be used, such as precipitation, electrowinning, or electrorefining. Precipitation involves adding a chemical reagent to the solution, causing the metal to precipitate as a solid. Electrowinning and electrorefining utilize electrical current to deposit the metal onto a cathode, resulting in a high-purity metallic product.

Refining:

In some cases, further refining steps may be required to achieve the desired purity level. This can involve processes like distillation, zone refining, or electrolytic refining, depending on the specific metal and its impurities. These refining techniques help eliminate any remaining impurities, ensuring the highest level of purity in the final metal product.

Benefits of Hydrometallurgical Processes for Pure Metal Extraction:

There are several advantages offered by hydrometallurgical processes for obtaining pure metals:

High Purity Levels: Hydrometallurgical processes enable the production of metals with high levels of purity, meeting the stringent requirements of various industries.

Selective Extraction: These processes allow for selective extraction of desired metals while leaving impurities behind, resulting in purer metal products.

Sustainability: Hydrometallurgical methods promote sustainable mining practices by minimizing the environmental impact associated with traditional extraction methods.

Recycling Opportunities: Hydrometallurgy also facilitates the recycling and recovery of metals from various secondary sources such as electronic waste, contributing to resource conservation and circular economy initiatives.

Conclusion:

Hydrometallurgical processes have revolutionized the extraction and purification of metals, making it possible to obtain pure metals with exceptional levels of purity. Through leaching, solution purification, metal recovery, and refining steps, these processes offer a sustainable and efficient approach to meet the increasing demand for pure metals in various industries. By leveraging the power of hydrometallurgy, we can ensure the availability of high-purity metals for technological advancements and sustainable development.