Advancements in Battery Scrap Recycling Technology

As our world becomes increasingly reliant on portable electronic devices and electric vehicles, the demand for batteries has surged. However, this growing demand has also led to a significant increase in battery waste, presenting a pressing environmental challenge. To address this issue, advancements in battery scrap recycling technology have emerged as a beacon of hope, offering a sustainable solution to manage and repurpose discarded batteries. In this blog, we will explore the latest developments in battery scrap recycling technology and their potential to shape a greener future.

|

Table of contents The Challenge of Battery Scrap Advancements in Battery Scrap Recycling Technology Efficient Sorting and Collection Systems: Mechanical and Hydrometallurgical Processes: Pyrometallurgical Techniques: Innovative Separation Technologies: Closed-Loop Recycling Systems: |

The Challenge of Battery Scrap

Batteries, comprising a variety of materials such as lithium, cobalt, nickel, and manganese, pose a significant environmental risk when disposed of improperly. The extraction of these materials from the earth can be environmentally damaging, and improper disposal can lead to toxic elements leaching into soil and water sources. Additionally, the demand for rare and valuable elements like cobalt and lithium has created supply chain concerns, making recycling an increasingly vital solution.

Advancements in Battery Scrap Recycling Technology

Here are some notable advancements in battery scrap recycling technology:

Efficient Sorting and Collection Systems:

One of the primary challenges in recycling battery scrap is the complex mix of materials and chemistries. Advanced sorting and collection systems have been developed to streamline the process. These systems utilize various techniques such as optical sensors, X-ray technology, and robotics to quickly and accurately identify and separate different types of batteries based on their chemistries and materials.

Mechanical and Hydrometallurgical Processes:

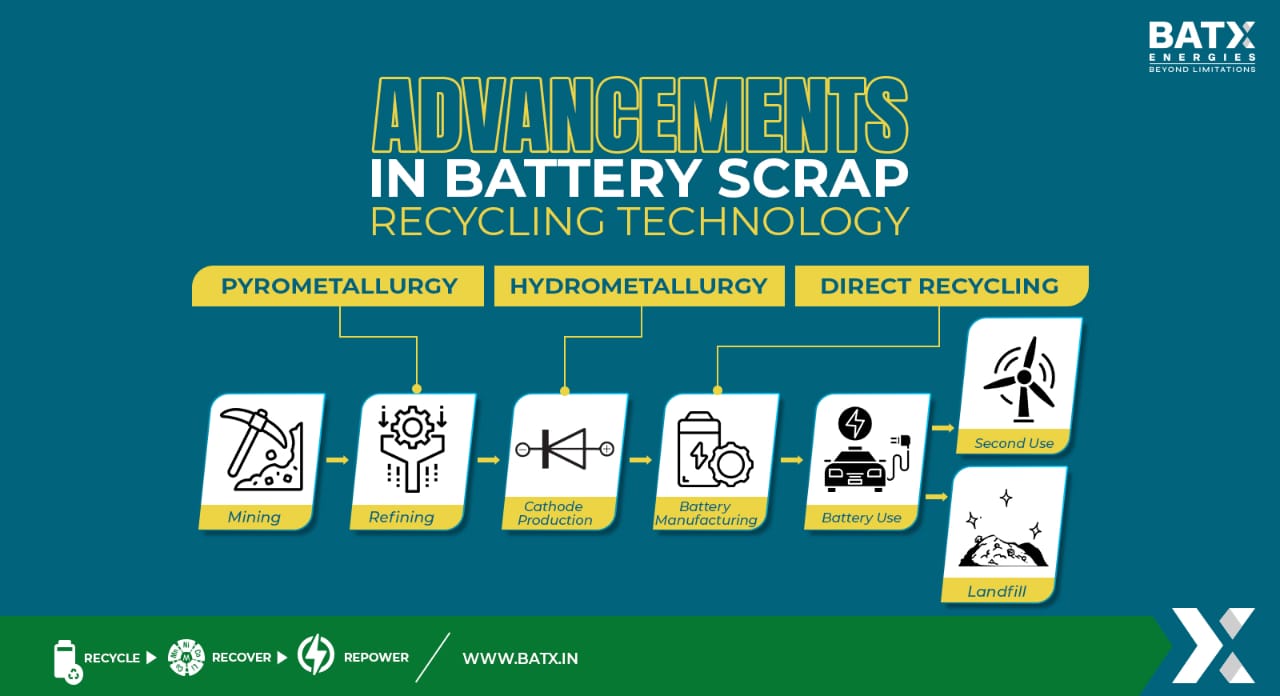

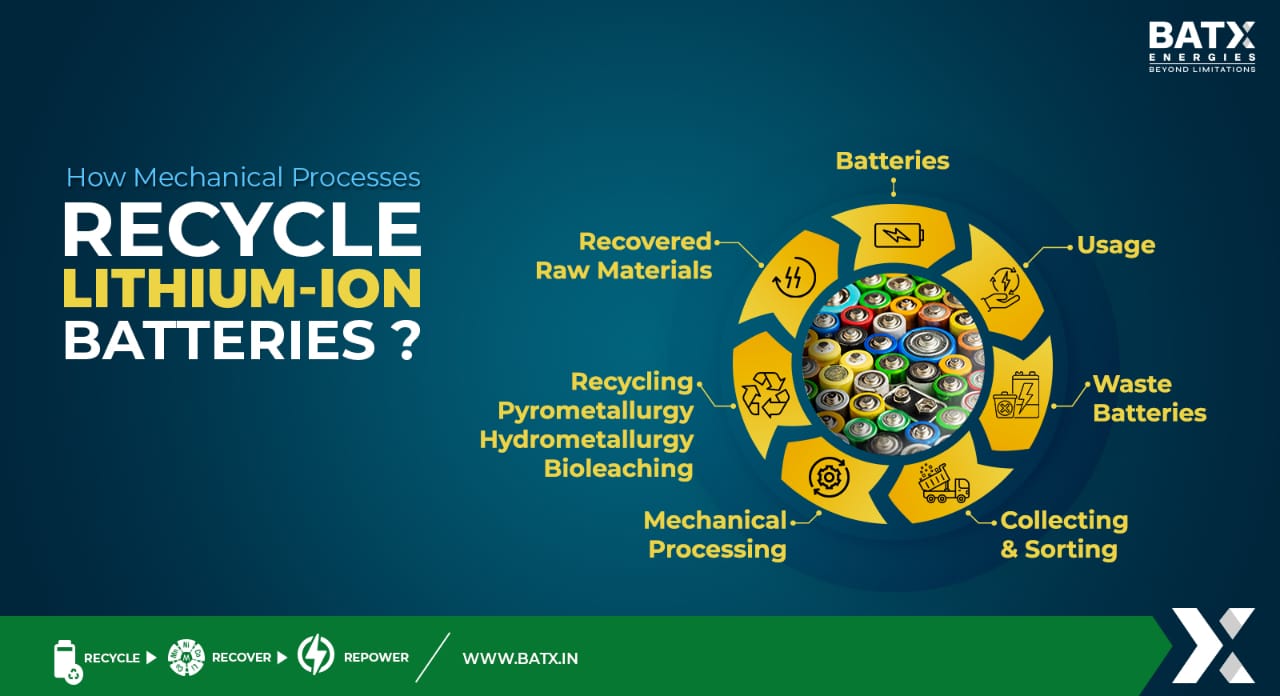

Recycling facilities employ mechanical and hydrometallurgical processes to extract valuable components from battery scrap. Mechanical processes involve crushing and shredding batteries to separate the different components. Hydrometallurgical processes, on the other hand, use chemical solutions to dissolve and recover metals from the battery materials. These methods have undergone significant advancements to improve efficiency and minimize waste during the recycling process.

Pyrometallurgical Techniques:

Pyrometallurgical techniques, such as smelting and high-temperature processes, have gained prominence in battery scrap recycling. These methods involve melting batteries at high temperatures to recover valuable metals. Advanced pyrometallurgical techniques not only allow for efficient recovery of metals but also minimize harmful emissions and reduce energy consumption, making the process more sustainable.

Innovative Separation Technologies:

Researchers are continually exploring innovative separation advancements to enhance the efficiency of battery scrap recycling technology. Methods such as froth flotation, solvent extraction, and ion exchange have shown promise in selectively separating and recovering specific metals from battery materials. By targeting individual metals, these methods improve the overall yield and purity of the recovered materials.

Closed-Loop Recycling Systems:

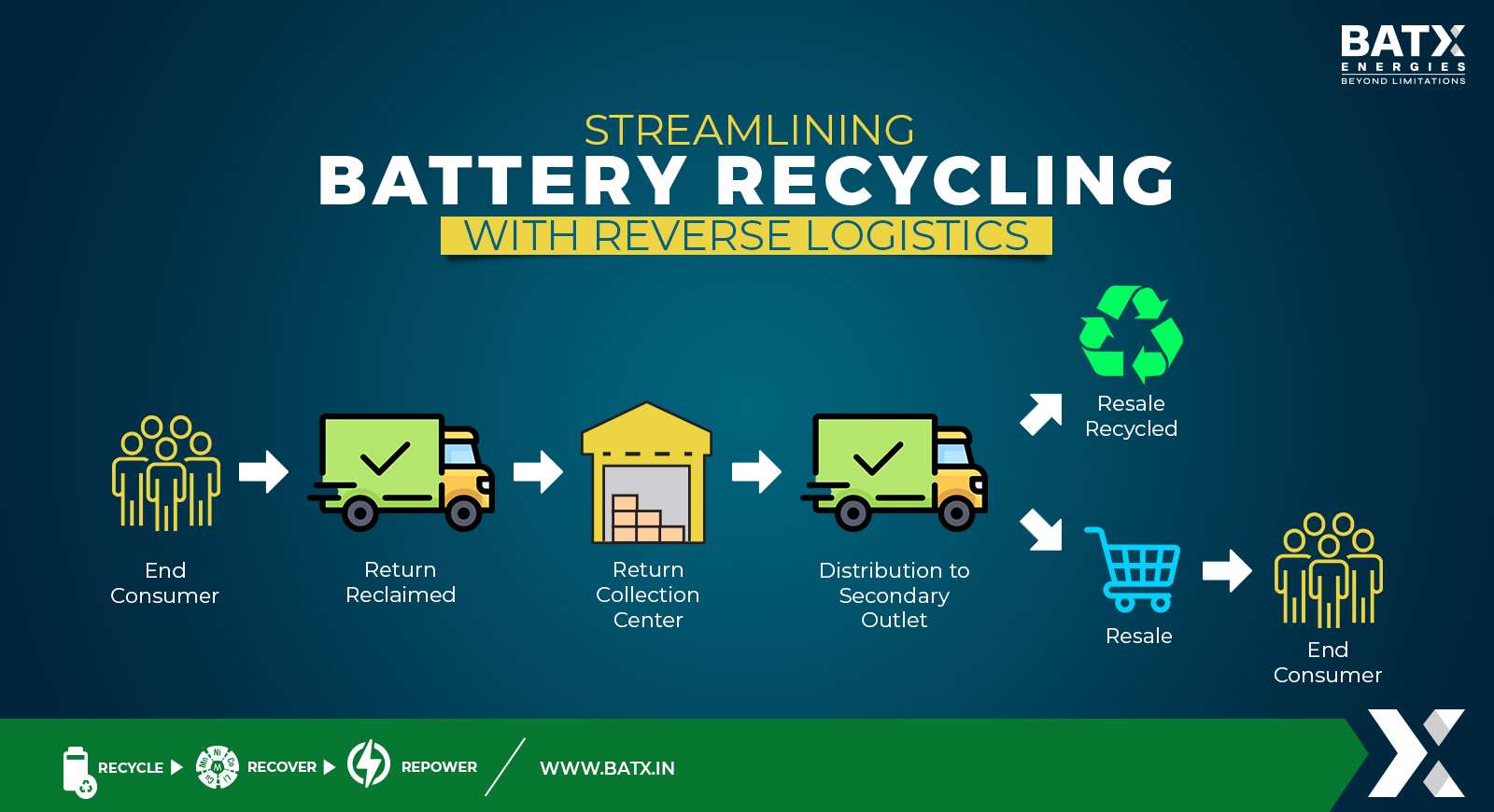

Closed-loop recycling systems aim to create a circular economy for batteries, where old batteries are collected, recycled, and used to manufacture new batteries. This approach reduces the reliance on raw materials, minimizes waste, and conserves energy. Several battery manufacturers and technology companies have already started implementing closed-loop recycling systems, contributing to a more sustainable battery industry.

The Benefits of Advanced Battery Scrap Recycling

The advancements in battery scrap recycling technology offer numerous benefits for both the environment and the industry:

Resource Conservation: Recycling battery scrap reduces the need for new raw materials, conserving valuable resources like lithium, cobalt, and nickel. It alleviates the environmental impact associated with mining and extraction, helping preserve ecosystems and reducing carbon emissions.

Waste Reduction: Battery recycling prevents the accumulation of hazardous battery waste in landfills, mitigating the risk of soil and water contamination. By recovering valuable materials, recycling minimizes the need for landfill space and promotes a cleaner environment.

Economic Opportunities: The growth of the battery recycling industry creates new economic opportunities, including job creation and the development of innovative technologies. Recycling facilities, research institutions, and startups focused on battery recycling contribute to the growth of a sustainable economy.

Supply Chain Stability: By establishing closed-loop recycling systems, the battery industry can achieve greater supply chain stability. Recycling reduces dependency on foreign sources of raw materials, ensuring a consistent supply of critical elements for battery production.

Conclusion

Advancements in battery scrap recycling technology represent a significant step toward building a sustainable future. These innovations offer efficient and environmentally friendly ways to recover valuable materials from discarded batteries, reducing the strain on natural resources and minimizing waste. As the demand for batteries continues to grow, embracing these recycling technologies is crucial to ensure a greener and more sustainable world. By promoting research, investment, and collaboration, we can unlock the full potential of battery scrap recycling and pave the way for a circular economy in the battery industry.