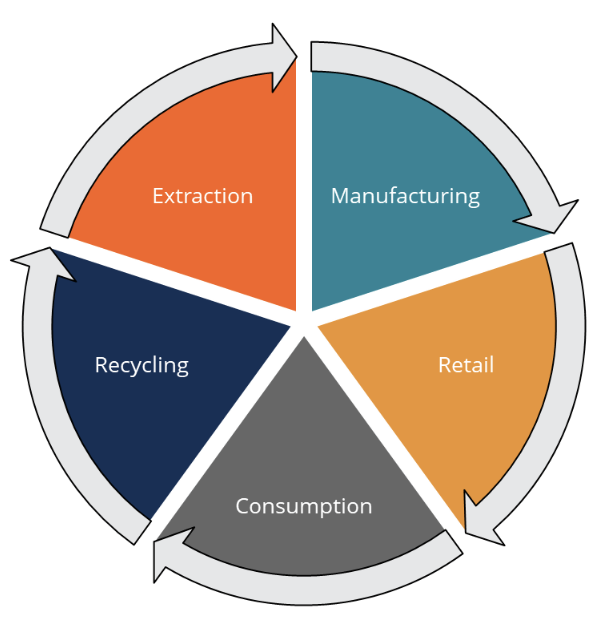

What will it take to transform our throwaway economy into one where waste is eliminated, resources circulated, and nature regenerated?

A circular economy is “a model of production and consumption, which involves sharing, leasing, reusing, repairing, refurbishing and recycling existing materials and products as long as possible”. Essentially, a circular economy describes a regenerative economic system.

It is the new paradigm for companies and industries to reduce their environmental impact and close the resource loops through circular flows between post-use and production.

A circular economy aims to extend the useful life of the products and materials by creating the loops of the materials and products circulating in the economy. The goal is achieved through the active reuse, repair, and remanufacturing of the products and materials utilized in the economy. It is the Industrial symbiosis viewed as a key strategy for companies towards the circular economy, that deals with replacing raw materials and production inputs of one production process with by-products and waste generated by another production process. In a world where natural resources are genuinely finite, resource depletion is ever rising, which has resulted in social and environmental negative effects.

New technologies often mean new ways of producing and consuming material and energy sources. In general, technologies are becoming more sophisticated, and products require the use of materials that are often non-renewable and scarce. The demand for Lithium has increased significantly during the last decade as it has become key for the development of industrial products, especially batteries for electronic devices and electric vehicles.

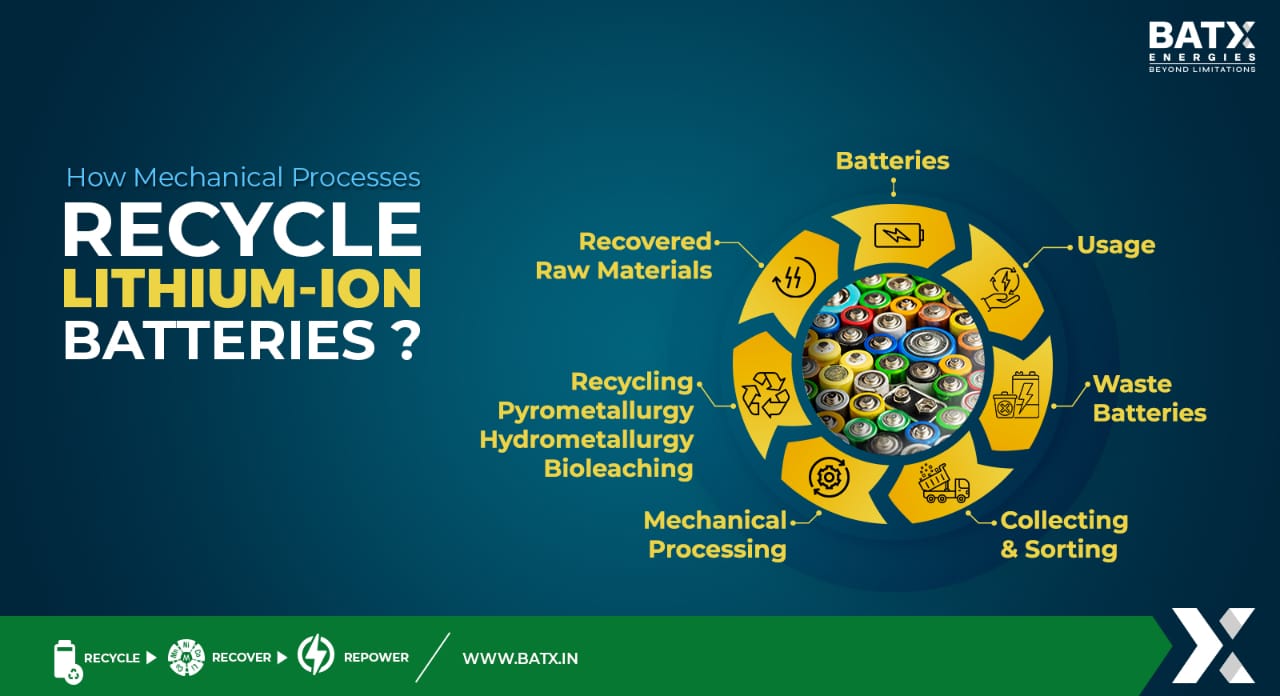

The reuse and recycling market for Lithium-ion batteries in the country is just coming into existence and there are very limited or almost no services and infrastructure in place to support reuse and recycling of Lithium-ion batteries. Moreover, the infrastructure, processes, and technology currently in place and available for the reuse and recycling of Lithium-ion batteries are not optimized for efficient cost-effective reconditioning or recovery of materials. As a result, reuse and recycling options are less readily available and are more costly than cheaper. In turn there is limited publicly available information and projects to demonstrate the quality, performance, safety, and technical viability of reused and refurbished Lithium-ion batteries which may also impact consumer trust and confidence in the reuse of the same. The global market for large-format Lithium-ion batteries continues to grow in response to increasing demand in electric vehicles (EVs) and energy storage.

Amid the growing debate about the compatibility of increasing consumption with the Earth’s finite resources, calls are getting louder for a system that minimizes losses. This concept is of great interest for Lithium-ion batteries not least as production of the batteries is expected to increase exponentially, given its key role transforming the mobility sector. Lithium-ion batteries have a high energy density compared to their size, which gives them an advantage over other batteries. They are expected to continue to dominate the electric vehicle market in the medium to long term.

Transitioning to a circular economy will radically change how the automotive industry approaches material design, use, and end-of-life processes. Many automakers have already announced sustainability targets in transitioning to a circular economy, and the table below lists some of these significant automaker announcements.

Examples pulled from automakers’ sustainability reports and press releases

2025

- BMW: One-third of vehicles BMW sells in Europe should be electrified

- Ford: Use 20% sustainable materials

- GM: 50% of all energy use in factories sourced from renewable sources & 40% of U.S. models offered will be EVs

- Nissan: Aiming for one million EV sales

- Toyota: Achieve a 25% introduction rate for renewable electricity

- VW: Reduce CO2 emissions per vehicle of all plants by 50%

2030

- BMW: Double the energy density of EV battery cells

- Ford: Eliminate single-use plastics

- GM: 100% renewable energy use in the U.S. for vehicle manufacturing; 31% GHG reduction from factories; & phase out fossil fuels. Set goal of offering only EV light vehicles by 2035

- Toyota: Complete establishment of battery collection & recycling globally

- VW: 75 new EV models

2050

- BMW: 50% of all vehicles leave factories via green logistics providers

- GM: 100% renewable energy use globally; carbon neutral in 2040

- Honda: Achieve carbon-neutral status

- Nissan: Achieve carbon-neutral status

- Toyota: Reach zero CO2 emissions across global plants & 90% reduction of CO2 from new vehicles

Although automakers have begun to announce their sustainability goals, the industry is far from a completely circular economy. Below is a list of a few elements industry stakeholders should consider to support their efforts to move towards this goal.

- Repurposing waste into materials/parts

- Utilizing renewable biomaterials

- Advancing separation & cleaning of materials

- Designing materials for longevity, recyclability, and disassembly

- Developing advanced recycling technologies

- Optimizing manufacturing processes

- Investigating recovery models

- Funding alternative R&D solutions

Suppliers and other stakeholders should be prepared for this transition to a circular economy to take a significant amount of time. The industry needs to anticipate and overcome numerous hurdles throughout this process. To support the transition policies, infrastructure investment and educational development will enable additional growth in innovative sustainability efforts across the automotive industry.