India is rapidly adopting electric vehicles to attain a sustainable mobility solution. One of the most expensive components in an electric vehicle is its battery. Thus, expanding and developing the battery supply chain is essential to achieving long-term electric vehicle goals. Sales of two-wheelers, especially high-speed two-wheelers, have increased by 425% since 2020. In 2021, 1,42,829 units were sold as opposed to 27,206 in 2020. However, while battery manufacturing is growing in India, the entire supply chain still relies on other countries.

Let’s understand why lithium-ion battery recycling is the best source to achieve the goal of the Indian electric vehicle industry.

Government Regulations Supporting Battery Manufacturers

The Indian government has implemented several measures over the past several years to create an environment conducive to the growth of electric vehicles. The government guaranteed a long-term boost for the EV industry through the Faster Adoption and Manufacturing of Hybrid and Electric Vehicles (FAME-I and II) initiatives. Still, it is also understood that the local battery cell production industry can also help to switch to environment-friendly transportation.

The Government of India provided the battery manufacturing industry with the largest share of the PLI scheme outlay with a significant commitment of Rs 75,000 Cr for Advance Chemistry Cell (ACC) Batteries and Automobiles & Auto Components. A PLI plan for the battery business called “National Program on Advanced Chemistry Cells (ACC) Battery Storage” with a budget of Rs 18,100 crore was also authorized by the government in May 2021.

The government aimed to produce 50 GigaWatt Hours of ACC to reduce the high import costs. These are crucial steps taken by India’s government to make the battery supply chain easier for the manufacturers.

Lack of Resources & Refining Capabilities

All of the metals required to make Li-ion batteries, including lithium, nickel, and cobalt, are concentrated in a small number of nations, many of which have unreliable political systems. However, the current global mining operations cannot produce enough lithium and other essential minerals to satisfy the rapidly increasing demand for these batteries.

It takes time and money to establish new mines. Additionally, mining causes various environmental problems, including the depletion of neighbouring water supplies and the contamination of the area around it with runoff waste, which has sparked protests against opening new mines. This current supremacy may provide long-term concerns, particularly regarding energy security.

Supply Chain Disruption

The outbreak exposed the dependence on imports and the fragility of indigenous battery manufacturers. Several global factors, such as supply-chain interruptions, geopolitical strife, and price volatility, hindered imports, placing severe resource constraints on the Indian electric vehicle industry.

Need for Lithium-ion Battery Recycling in India

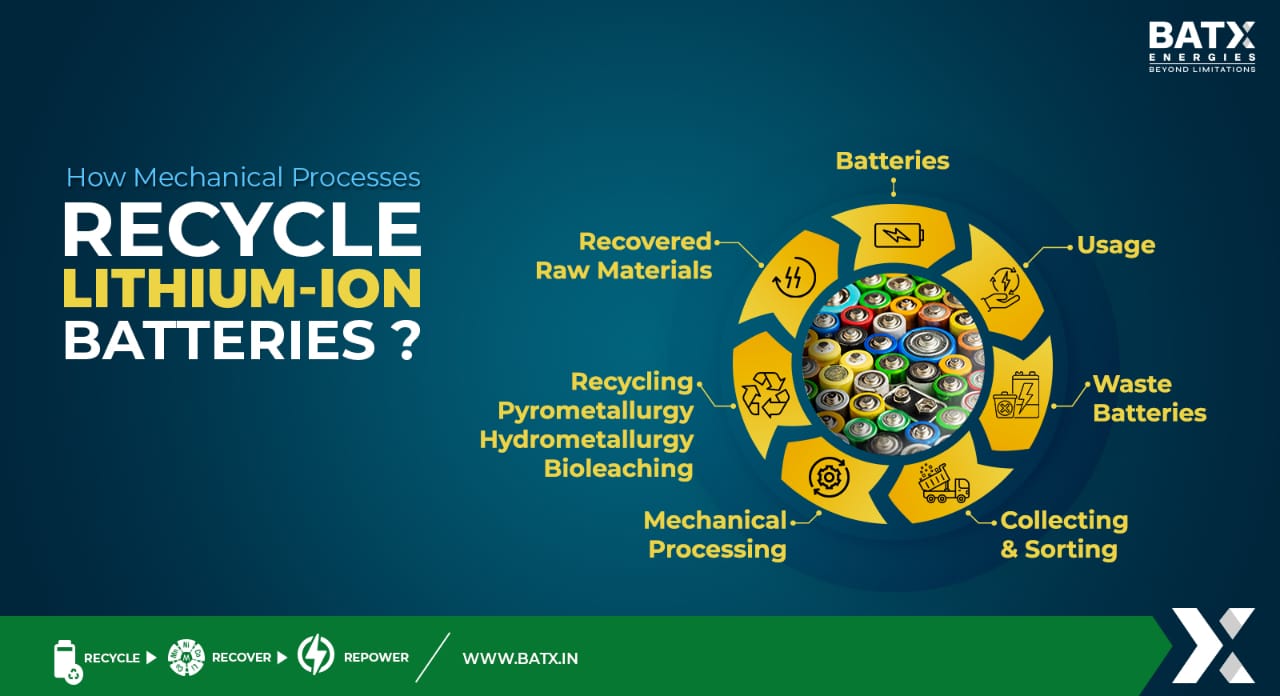

To solve the problems related to manufacturing lithium-ion batteries, there is a need to improvise the local supply chain. Upstream cell production demands raw materials, chemical refinement, and cathode production. The country becomes more independent when local supply chains are developed.

However, getting raw resources is the first step. India’s best option for improving domestic battery metal production and extending opportunities in other supply chain sectors is recycling end-of-life li-ion batteries, especially in the lack of domestic natural reserves. Recycling offers Indian businesses a competitive edge in sourcing essential battery components and a solid foundation in the EV ecosystem.

Developing a large-scale capability to recover valuable metals from used batteries has become a crucial milestone for all nations worldwide. This new focus has evolved due to raw material scarcity, supply chain constraints, and the potential to reduce the carbon footprint of mining activities. Governments and businesses quickly realize that a reliable supply of essential metals is necessary to achieve electrification goals. India should take this approach, and it should make use of the recycling opportunity to lower major supply chain risks.

BatX Energies is one of the battery recycling companies established in India to produce battery-grade materials by recycling end-of-life Lithium-ion batteries to create a sustainable energy source.